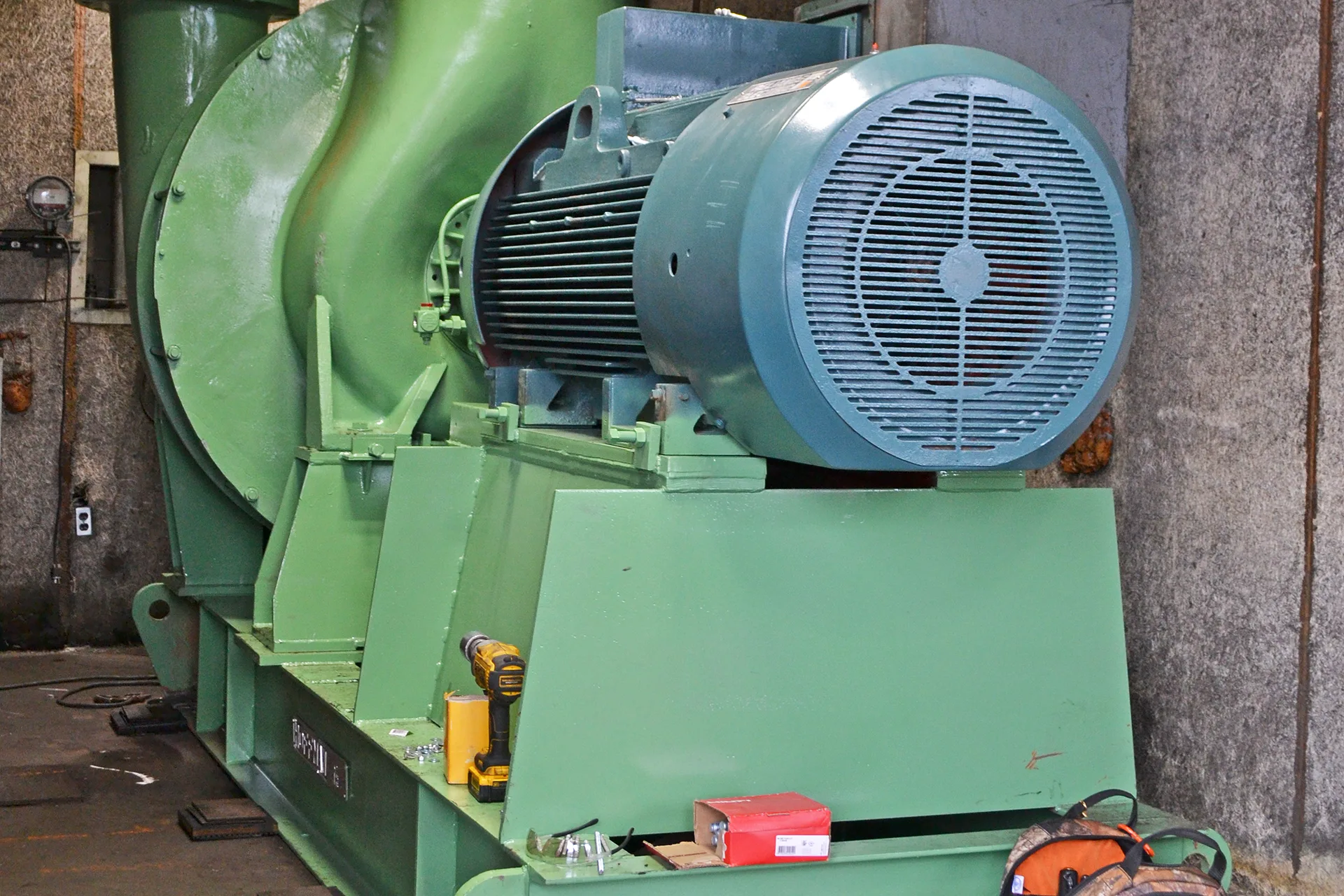

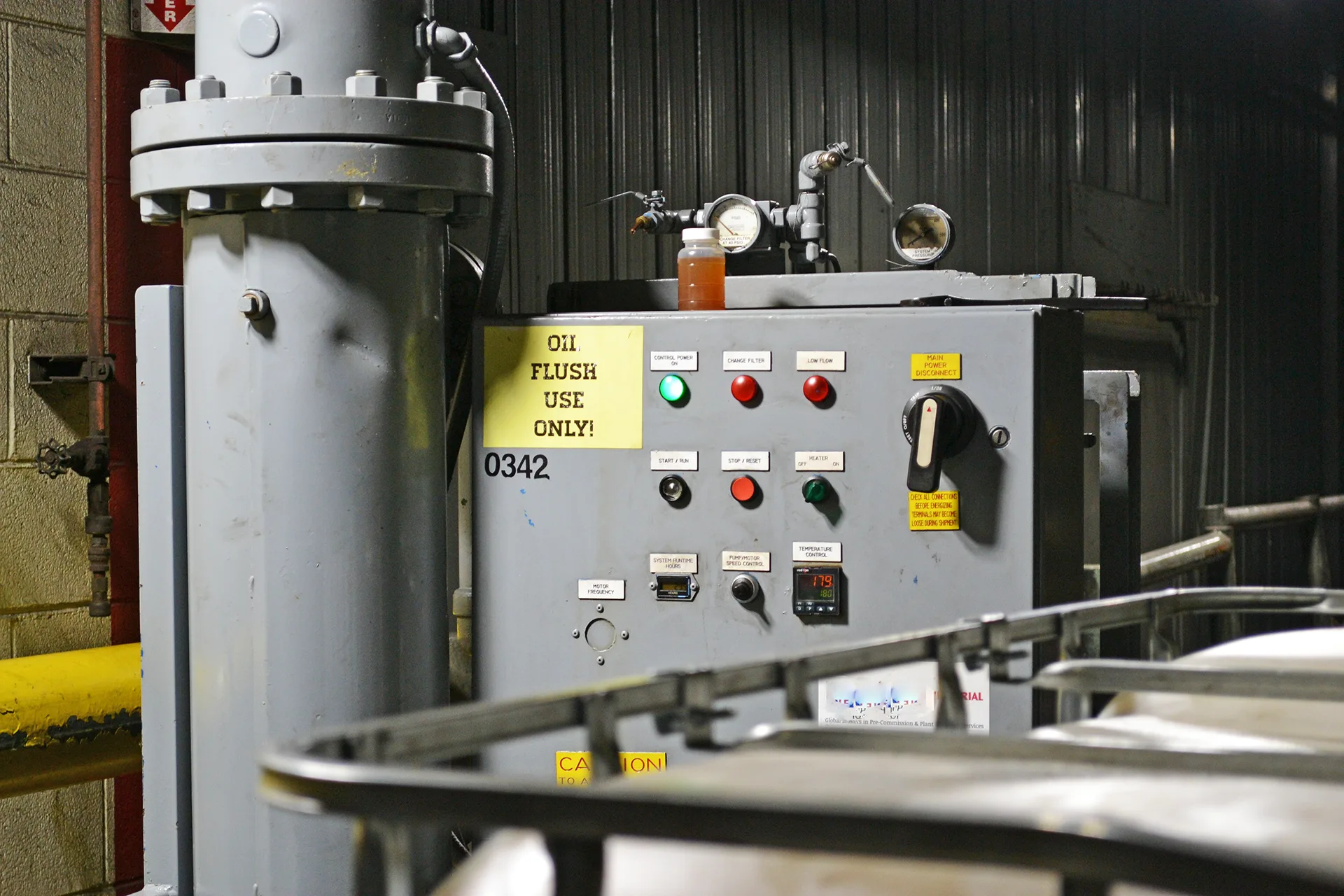

Used oil analysis is a quick, nondestructive way to gauge equipment health. Depending on where your program is at, Zudak works with you to develop and implement a program that makes sense for your plant, Zudak offers a variety of services including on-site sampling services, lab oil analysis, personnel training, and oil analysis audits. (Download Service Profile)

We provide you with a comprehensive report capturing equipment condition, identified issues, relevant trends, and actionable recommendations to prevent unscheduled downtime and costly repairs.