What is Vibration?

Vibration is a natural consequence of moving and rotating parts in industrial machinery components (e.g., belt-drive motors, shafts, bearings, gears, etc.). When considering vibration in asset operation, it is important to contextualize the vibration to the equipment of interest to assess whether the vibration is benign or indicative of a serious problem. Some starting questions to make are, “Is vibration part of fundamental machinery functionality, and if not, how much vibration is “normal” to that specific piece of equipment?”

If the vibration is indeed problematic, further analysis is necessary to discern the nature (forced vs resonant), the severity, as well as the vibration’s direction, amplitude, frequency, and phase characteristics. Problematic vibrations in the shape of large shaking, shock pulses, and abnormal noises translate to accelerated wear, increased unplanned maintenance, decreased production quality, as well as decreased plant safety.

What Causes Vibration?

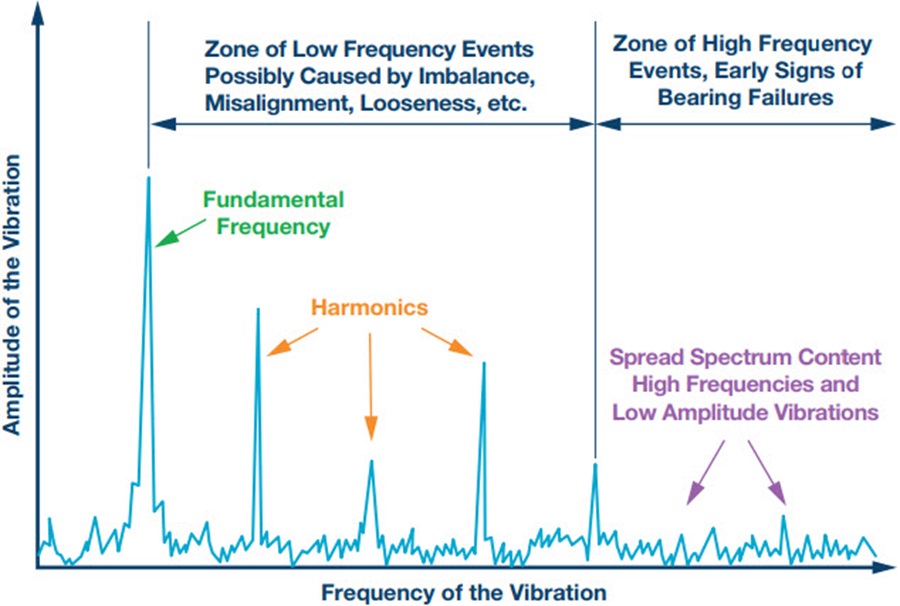

Causes for vibration are varied and wide-ranging; from improper installation to manufacturer defects, to natural wear. Diagnosis of specific vibration issues are primarily interpreted and understood through their amplitude and frequency footprints in a Fast Fourier Transform (FFT) graph, where vibration amplitudes are expressed as peaks at specific frequencies obtained from sensors or other monitoring systems.

The operating frequency of an asset is often illustrated as the first tallest peak in an FFT graph (known as the fundamental frequency), and subsequent multiples of that fundamental frequency are called harmonics, as shown below.

Vibrations in a machine follow two main response categories, forced or resonant.

A forced response is an imposed periodic external force (forcing function) that causes vibration. A resonant or free vibrational response is most commonly caused by forcing functions that are short in duration, very much similar to the decayed vibrational response car suspensions experience after hitting a bump in the road. Generally, problematic vibrations are a consequence of either or a combination of these response profiles.

Forced – (Periodic & Oscillatory Forcing Functions)

Experienced as repeated rotational forces in asset, frequency content is often found as multiples/orders of machinery rpm (fundamental frequency).

Imbalance – When the center of mass differs from the center of rotation.

Misalignment – When shaft centerlines of two directly connected components meet at angles and/or are offset from each other.

Free – (Impact & Transient)

The vibrational response is from a brief external force, frequency content is varied and often not correlated to operating RPMs.

Mechanical Looseness – Undesired looseness in internal components, footing, or machinery structure.

Anti-Friction Bearing Defects – Localized cracks, pits, spalls, and/or distributed surface roughness due to wear or manufacturing error.

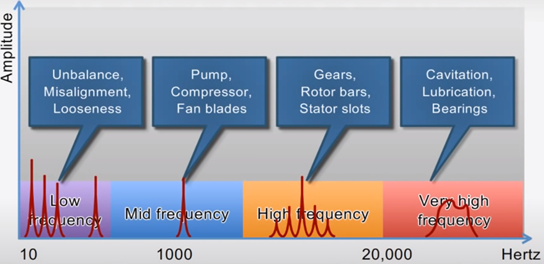

See below for more examples of vibration-inducing issues, related equipment, and their corresponding frequency bandwidth content.

How to Mitigate Vibration?

Due to the variety of causes that harmful vibration encompasses, prevention and damage mitigation is only as strong as the diagnosis and analysis involved in identifying root causes.

- The most ideal strategy is to have predictive/proactive maintenance strategies in the shape of continuous monitoring systems for rotating assets.

- The next best strategy is to perform routine preventative vibrational inspections in the form of conventional accelerometer-based vibrational analysis, which is best suited to identify mid-to-high frequency vibrational issues.

- For low-to-mid frequency vibrational issues, a contactless motion amplification service can be used to simultaneously illustrate root-cause issues before a catastrophic failure can occur.

Further Reading/Sources:

- “A Brief Tutorial on Machine Vibration” by Victor Wowk, PE

- “Practical Solutions to Machinery and Maintenance Vibration Problems”, Online textbook graciously provided by Update International, Inc.

- Mobius Institute’s extensive vibrational analysis catalogue on YouTube.

- RDI Technologies website featuring their revolutionary motion amplification invention.

Zudak Solutions employs Motion Amplification® to effectively diagnose vibration-related issues affecting your assets. If you have any questions about Motion Amplification® or any other service we offer, contact us!

Leave a Reply

You must be logged in to post a comment.